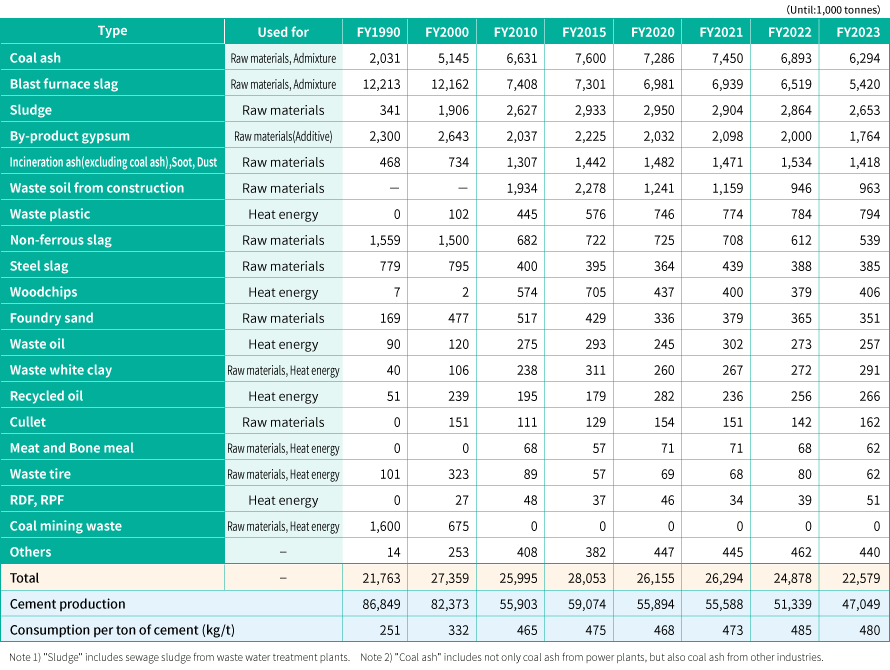

A lot of wastes, by-products and garbage generated from industries and households actually consist of the same constituents as those found in cement. Taking advantage of the fact that no secondary waste, and only a negligible amount of dioxin, is generated in the process of cement production, the cement industry is striving to recycle waste materials and by-products. Effective use of waste materials and by-products not only contributes to saving natural resources but also helps with extension of a remaining life of final disposal sites for waste materials which is currently a nationwide issue.

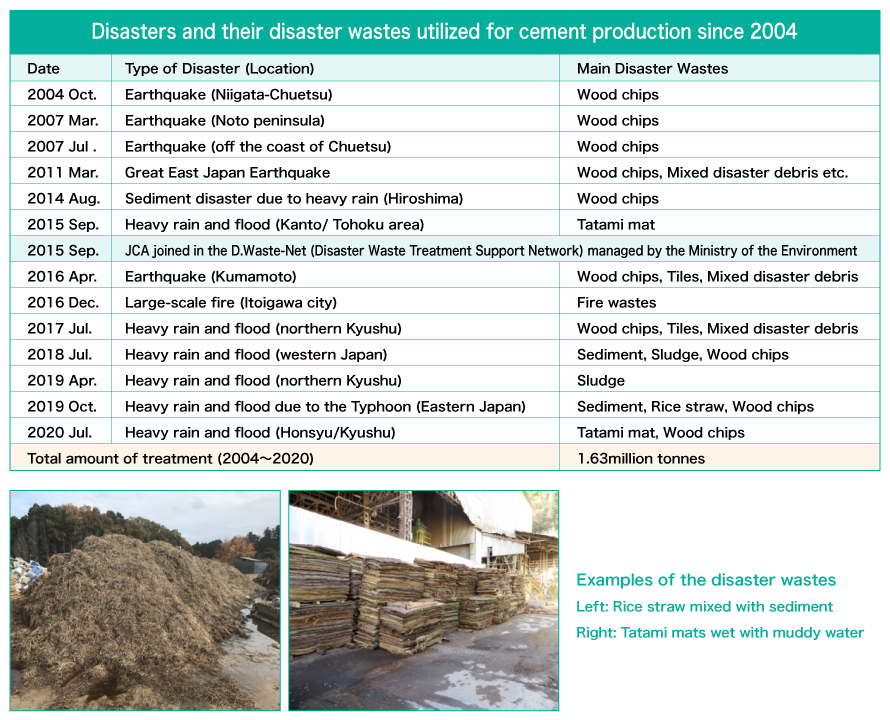

On the other hand, the cement industry supports the recovery and reconstruction of disaster areas by usingdisaster waste as a raw material and energy for cement production.