Strategies for carbon neutrality in the cement industry

In March 2022, Japan Cement Association announced the “Long-term Vision for the Cement Industry toward Carbon Neutrality” subject to the direction of the Japanese government's green growth strategy and others.

(https://www.jcassoc.or.jp/cement/1jpn/220324.html)

1. The vision shows a forecasted cement demand and our actions and challenges

- Direction of our vision

- National Broad Demand

- Roles of the cement industry: "Supply of basic material," "Contribution to an establishment of a recycling-based society," "Contribution to local community," "Cooperation in disaster debris treatments," etc.

- Direction of measures and issues to be challenged: "Reducing clinker to cement ratio" "Switching to low carbon raw materials and thermal energy" "Improving thermal energy efficiency" "Development of low carbon binding materials and new cement" "Challenging to CCUS" "Taking up CO₂ by cement carbonation" etc.

2. Outline of Action Plan on the Carbon Neutrality

1) Pledge of Sector Target by 2030

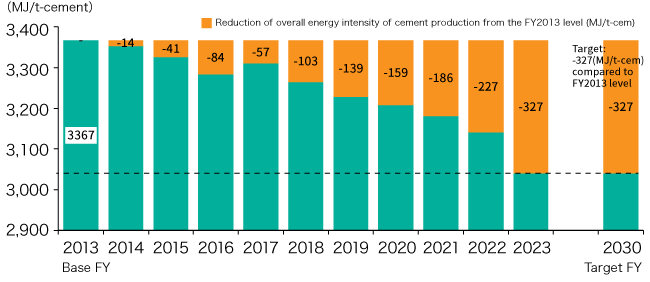

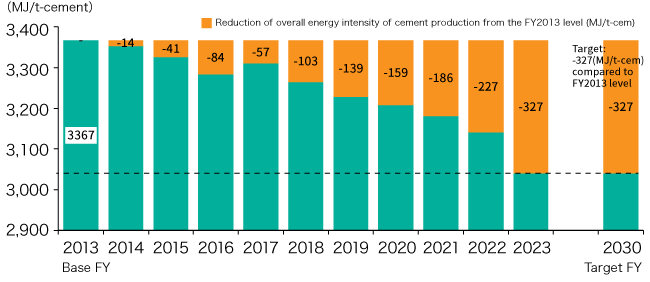

① Reduce a specific overall energy consumption of cement production (*1) (*2) 327 MJ/ton-cem. in FY 2030 from the FY 2013 level.

- (*1) “Specific overall energy consumption of cement production” is calculated as the summation of “Specific thermal energy consumption of cement production”, “Specific thermal energy consumption for on-site power generation” and “Specific electrical power energy purchased from the grid” divided by “Cement production volume”, where alternative thermal energy from combustible wastes is excluded.

- (*2) “Specific overall energy consumption of cement production measured for the fiscal assessment year” is slightly compensated by taking into account of fluctuations of “cement production volume” and “clinker/cement ratio” from the base year (FY2013) levels as “specific overall energy consumption of cement production”.

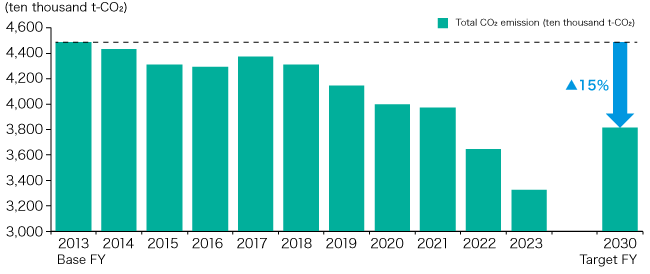

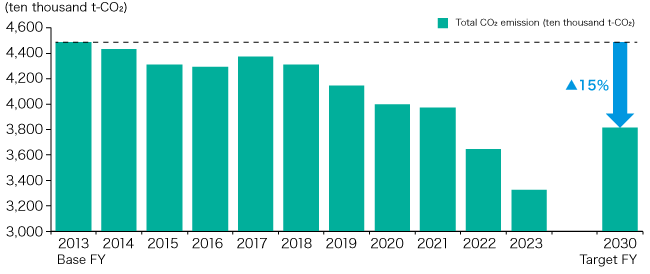

② Reduce 15% of total CO₂ emission (*3) in FY 2030 from the FY 2013 level (*4).

- (*3) This includes both of energy and process-related CO₂ emissions.

- (*4) Each target will be revised according to progress results or market circumstances.

2) Other Actions on Low-Carbon Products and Services

① Encouragement of diffusion of concrete pavement : CO₂ emitted from a heavy vehicle to drive on concrete pavement is reduced due to an improvement of mileage on a point of view of a life cycle assessment (LCA).

② Contributions to the establishment of the recycling-based society: Utilization of many types of combustible wastes and by-products from other industries for cement production results in extension of a remaining life capacity of existing landfill sites.

3) Contributions to the global mitigation

Statistical national information on energy consumption, diffusion rate of energy conservation technologies (equipment) and utilization of alternative fuels has been published to the public in order to contribute both to the reduction of an energy consumption to produce cement and the establishment of the recycled –based society globally.

4) Development of technologies(Plan after FY 2022)(*5)

① Specific thermal energy consumption of cement production can be reduced by using mineralizer which decrease the burning temperature of clinker.

② Specific thermal energy consumption of cement production can be reduced by increasing the amount of C₃A in the clinker and clinker substitutions in cement.

-

(*5) Under the right conditions of expected circumstances and technique such as availability of material containing fluorine, optimized clinker production conditions and quality control method for the aimed clinker, a feasible study for the clinker production would be carried out in an appropriate plant for the pilot test.

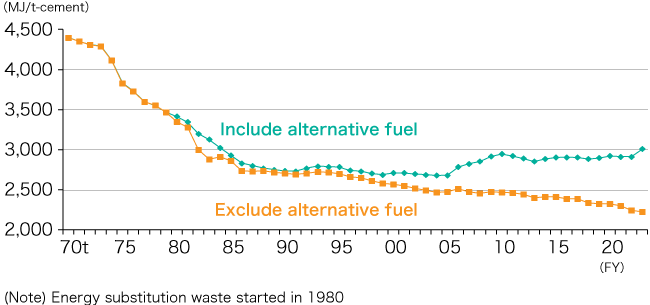

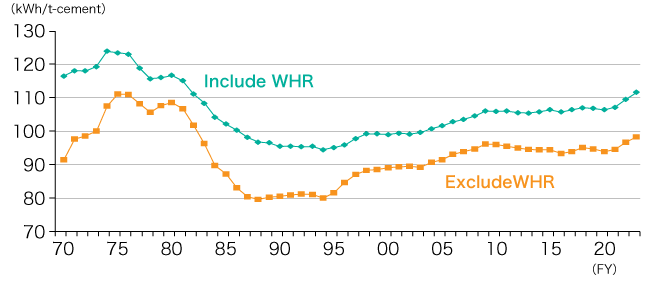

The specific energy comsumption for cement production

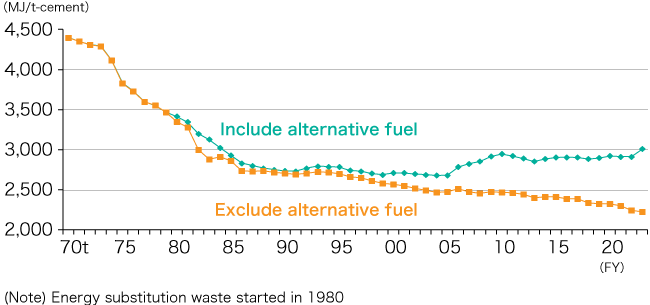

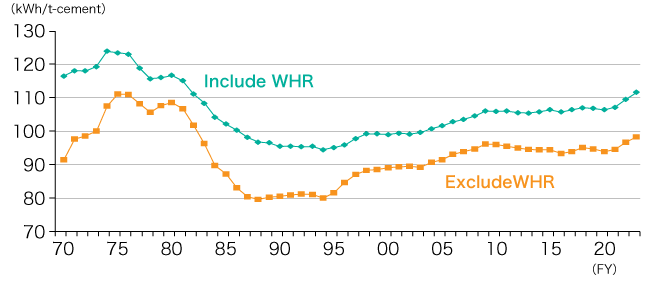

The cement industry has tackled energy efficiency for cement production, this action has played an important key role in the Carbon Neutrality Action Plan.

Specific thermal energy comsumption

Specific electric power comsumption

3.Challenges to CO₂ reduction and measures towards 2050

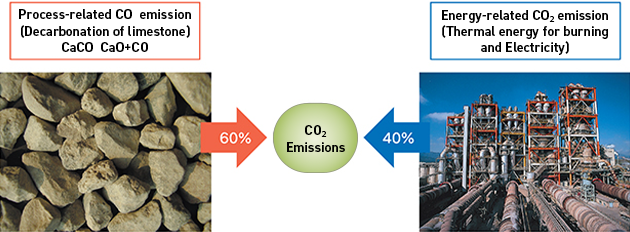

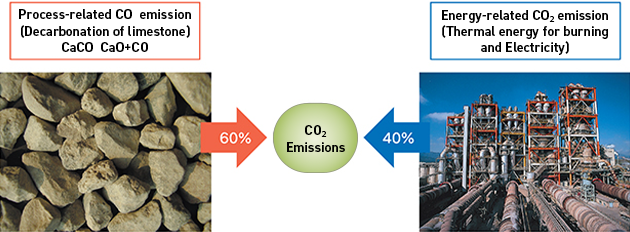

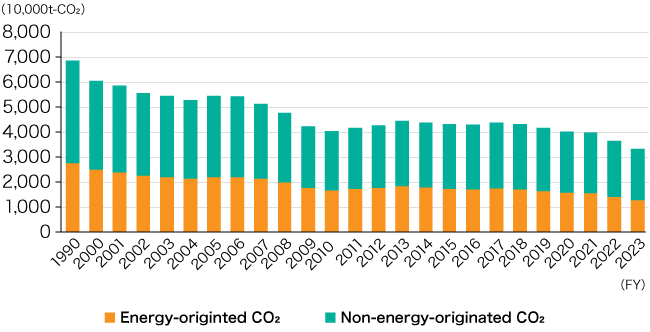

CO₂ emission from the cement industry is consisted of both decarbonation of limestone as main raw material(process-related CO₂ emission) and emission from energy used in cement manufacturing (energy-related CO₂ emission).

CO₂ emissions

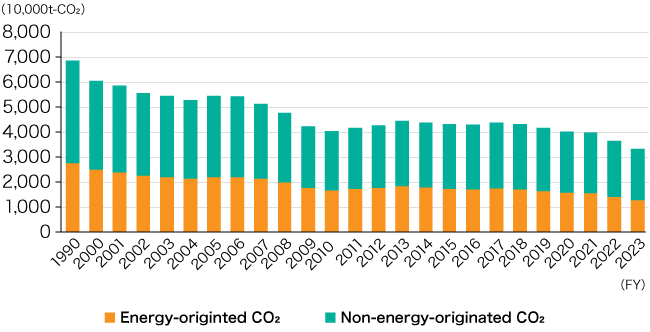

The cement industry has worked on reducing specific energy consumption of cement manufacturing by the voluntary action plan.

In order to contribute to Japan's carbon neutrality in 2050, we continue to reducing both “process-related CO₂ emission” and “energy-related CO₂ emission” as possible.

Measures towards a Carbon Neutrality in 2050

(1) Process-related CO₂ Emissions

- Aiming at reducing a clinker to cement ratio from 0.85 to 0.825 by adding mainly minor additional constituent for the ordinary portland cement.

- Taking into consideration that substantial natural CO₂ uptake by cement carbonation has been reported. However, since no accounting methodology is internationally established, a range of estimated volume presents as a contribution to the carbon neutrality by the cement industry.

(2) Energy-related CO₂ Emissions

- Enhancing a reduction of energy consumption for cement production using energy conservation technologies, increasing alterative energies delivered from wastes and reducing the clinker to cement ratio.

- Aiming at replacing at least by 50% of zero-emission alternative energies from fossil energies for calcination using co-firing of hydrogen and ammonia and furthermore methanation, and co-processing with various wastes and biomass.

- Aiming at achieving net-zero emissions from the on-site power generation facility converting to alternative energies and biomass.

(3) Carbon Capture, Utilization and Storage (CCUS) for both CO₂ Emissions

- Aiming at reducing CO₂ emissions through CCUS technologies while promoting technology developments in line with the national Green Growth Strategy through Achieving Carbon Neutrality in 2050, etc.

(4) Further Reduction in Future

- As an increase in users awareness of the need for zero carbon products, further innovative technologies are considered and also the clinker to cement ratio targeted at 0.825 in 2030 is expected to be 0.8 in 2050 by adding additional cement constituents.